How Can 3D PDFs With Model Based Definition Improve Production

What is Model-Based Definition and 3D PDF?

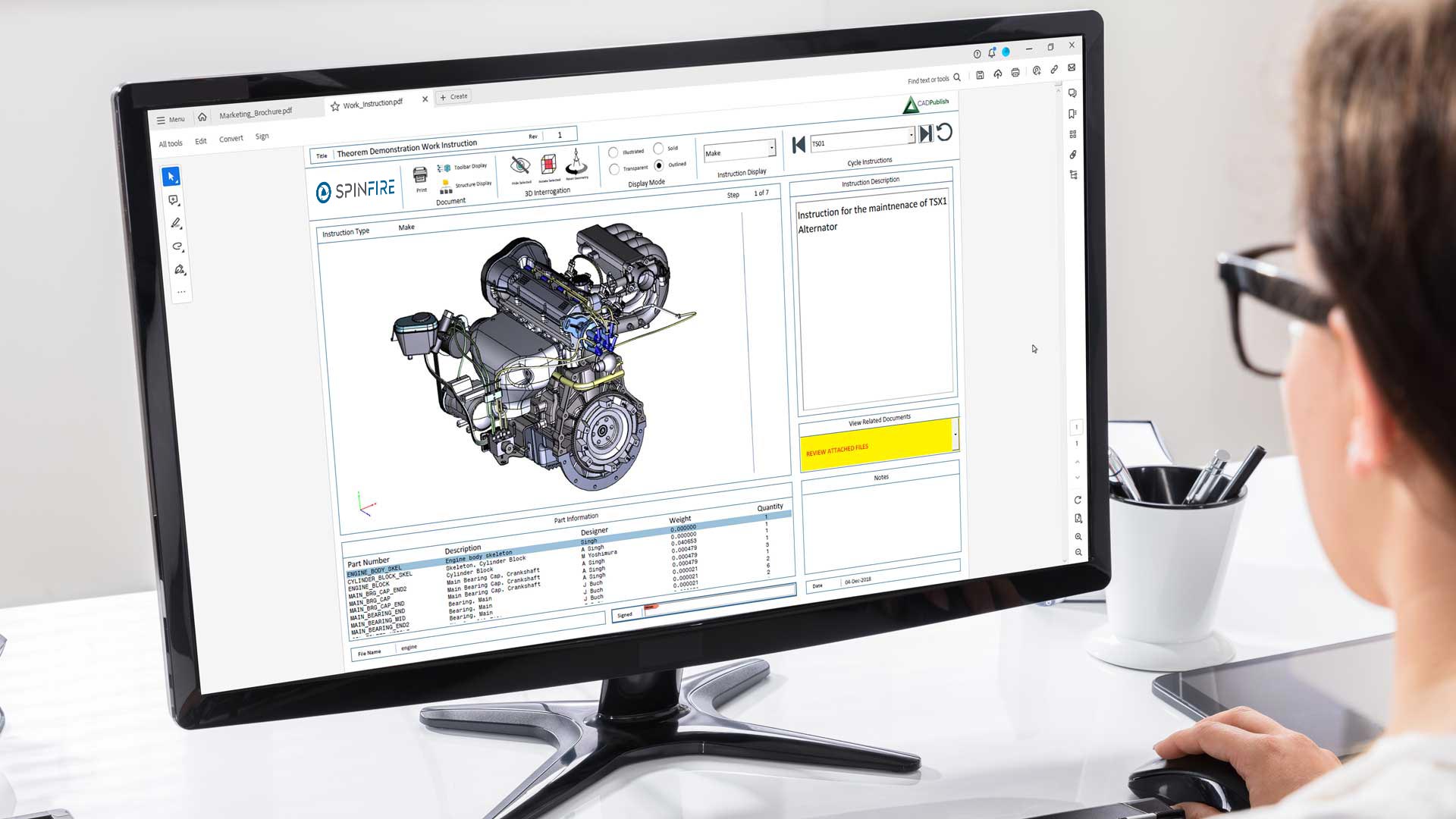

Processes utilizing model-based definition (MBD) contain manufacturing information alongside 3D CAD models. By including annotations, dimensions and more alongside your 3D model, you can provide important context when collaborating with your 3D data. Sharing this data with someone who doesn’t have the same CAD software can be an issue though, but with 3D PDFs this isn’t a problem. 3D PDFs contain interactive 3D models in the very sharable PDF format. With a tool like SpinFire Convert this data is taken straight from native source CAD and can include the information needed in MBD practices.

The Evolution of Modern Day CAD

Previously, technical drawings of a product (along with accompanying information such as dimensions and tolerances) had to be done on paper by hand. This often results in many pages of information being required for a single component. Another problem when working with these technical drawings is that a skilled engineer is required to read them, and they may still be misinterpreted.

Modern 3D CAD applications allow users to include manufacturing with a single 3D model, without the need for flipping through multiple sheets of paper. From this MBD practices became possible. As 3D CAD computer software started to become the norm some of the difficulty of using traditional 2D drawings was removed, but sharing this information still poses some problems.

Sharing Data is Easier with PDFs

Even with all the necessary data being available digitally, it can still be difficult to share it with people who don’t have your CAD system, or people who don’t use CAD at all. This problem can be solved with 3D PDFs.

All that’s needed to open a 3D PDF is the free Adobe Acrobat Reader, making them the perfect way to share information with anyone. With a 3D PDF you can create a document with an interactive 3D model that can be re-orientated, sectioned or hidden to make visualization more effective. It can also be marked up and annotated, and users are able to attach additional data (such as images, PowerPoints and spreadsheets) to the 3D PDF.

Since they can also contain PMI, assembly structure, geometry, attribute information, and metadata alongside the 3D model, they can also be a part of your MBD processes.

Time is Money

Using 3D PDF with MBD reduces costs and time to manufacture. Also, since the native CAD models themselves are not being exchanged, data is shared without the need for additional CAD licenses, saving money if users need to share CAD information.

Plus, since 3D PDF reduces the likelihood of errors arising from engineers misinterpreting the data, companies will have to spend less time and money fixing any errors that arise from the interpretation of drawing data.

Final Thoughts

Model based definition (MBD) is a process that allows all the required information for manufacturing to be included on a 3D CAD model. Although this is a powerful tool, sharing this data with others is difficult if you do not have the same CAD software. Fortunately, 3D PDFs provide a solution. They can be accessed by anyone using the free Adobe Acrobat reader, so they’re easy to share. These PDF documents contain 3D CAD data, along with MBD information. This saves companies time and money since all the information required can be included on one shareable document.

To learn more, get in touch with our team of specialists, or request a 3D PDF evaluation today.