3D Software for Processing Polygon Meshes

MachineWorks' Polygonica powers innovative 3D software with robust 3D meshing functionality including automatic mesh repair, offsetting, model simplification and more.

With a partnership dating back to 2014, Polygonica and the HOOPS toolkits have been integrated into many of the world’s leading 3D and manufacturing applications. Developers can start with leveraging HOOPS Exchange to access over 30 industry-standard CAD formats including SOLIDWORKS, Catia, Creo, Inventor, STEP, and STL. Then, teams can use Polygonica to process geometry and render rich, interactive 3D visuals using HOOPS Visualize.

Features & Benefits

Healing

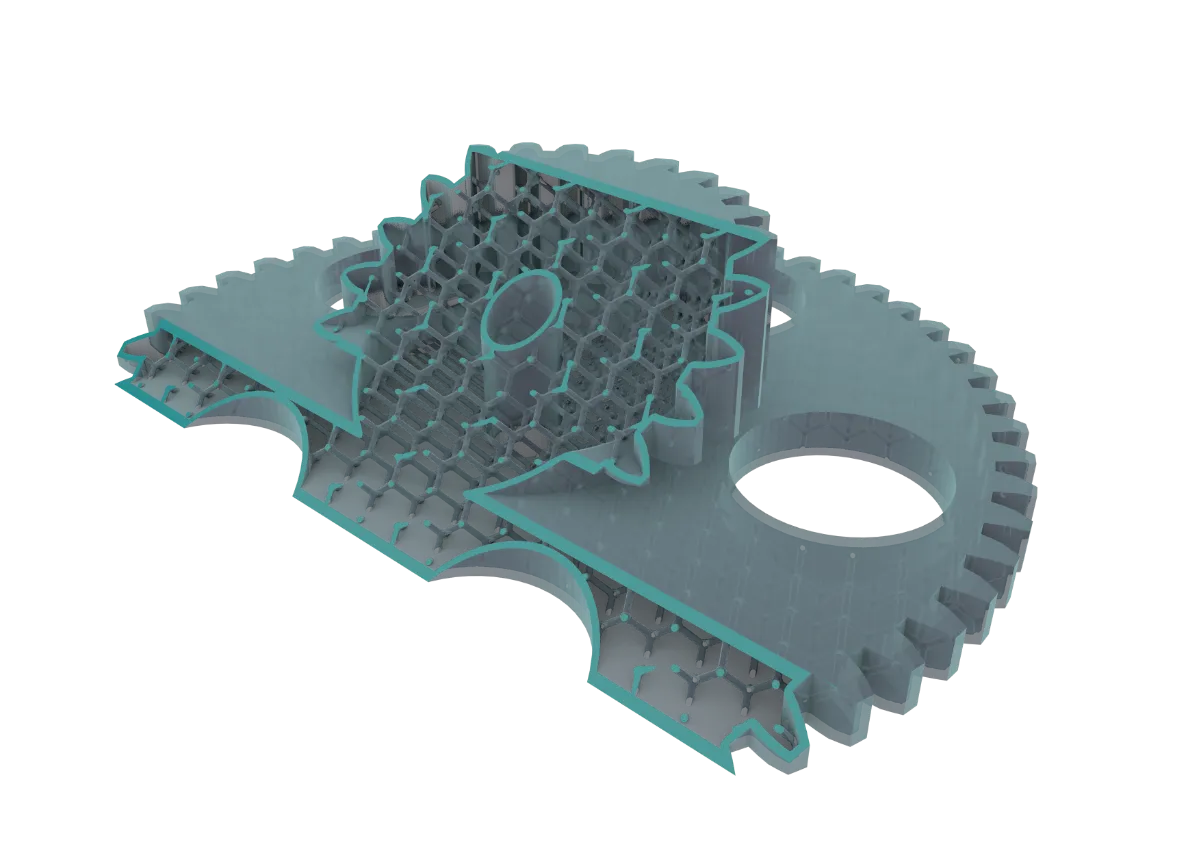

Polygonica quickly and reliably closes solids, fixes self-intersections, removes noise shells, and more, on a variety of file types and sizes. Eliminate overlapping triangles in 3D printing, creating error-free meshes for CAE analysis, and in advancing any workflow requiring closed, watertight models.

Boolean Operations

Perform unions, subtractions, and intersections accurately and instantaneously, even when done successively on large models. These powerful Boolean capabilities are perfect for removing errors or unwanted components prior to 3D printing, combining objects for CAE, and much more.

Offsetting

Polygonica's no-fail offsetting tools allow for smooth 3D printing. Users can offset down in order to hollow a model and save material or offset up to account for shrinkage after cooling. Offsetting is also helpful for polygon-driven applications and generating 3D solids that show possible collision areas for any given tolerance in Robotics.

Simplification

Maintain visual quality while reducing the size of a polygonal model for improved performance and downstream use. Simplify massive models to a manageable size to work with 3D printing software. Smaller data sets also enable better collaboration via 3D PDF or other 3D CAD viewers. This functionality works well for 3D Printing, CAE, CAD, Digital Construction, and Robotics.

Clash Detection

Fast clash detection from Polygonica ensures that points of intersection are identified and corrected at an early stage. This functionality is critical for intersection checking and simulation in EDA, Robotics, and BIM.

Popular Workflows

Additive Manufacturing

Fix errors, heal & repair, prep data, slicing & 2D processing

Generative Design

Constraint preparation, auto-heal, Boolean, & optimization calculation

CAD

Model reference, scan to mesh & heal, direct modeling with Booleans, export downstream

CAM

Analyze model with feature detection, toolpath generation, & simulation

Medical & Dental

Generate model from point cloud to mesh, smoothing, and model editing with Booleans

CAE

Data preparation, auto heal, decimate, surface and feature detection, Boolean, offset, defeature, shrink-wrap, isolate internals, remesh

This Windows desktop application showcases how Tech Soft 3D and MachineWorks SDKs can work together to create a powerful 3D Printing application. Mesh data loads into MachineWork’s Polygonica SDK, which analyzes it for 3D printing. Polygonica displays and heals errors, simplifies meshes, and hollows solids. Watch the video to learn more.

Frequently Asked Questions (FAQ)

Why does Tech Soft 3D resell Polygonica?

Tech Soft 3D resells Polygonica as a complement to our HOOPS SDK offerings. Many developers who need 3D data access, visualization, and simulation solutions also benefit from having a solid-modeling kernel as part of their stack.

By providing Polygonica as an option for our partners, we streamline the purchase and integration process.

Does Polygonica integrate with any of Tech Soft 3D's other SDKs?

Yes, Polygonica integrates with our HOOPS SDKs. In particular, the integrations between Polygonica and both HOOPS Exchange and HOOPS Visualize are tight.

HOOPS Exchange provides CAD data access that can be imported and leveraged by Polygonica.

HOOPS Visualize provides a graphics engine, where models created by Polygonica can be viewed.

What are the benefits of Polygonica?

For many applications, from additive manufacturing to simulation, strong, watertight models are essential. Polygonica provides the tools you need to create reliable geometry quickly and consistently, helping you avoid downstream errors and wasted time.

Some of the key benefits include:

Healing – Automatically repair gaps, overlaps, and other mesh issues to generate watertight, manufacturable models ready for 3D printing, visualization, or simulation.

Boolean Operations – Combine, subtract, and modify objects with robust operators that succeed even on imperfect meshes. Ideal for removing errors, merging assemblies, or cutting away unwanted geometry.

Offsetting – Easily hollow out parts to save material, or generate offset solids to visualize clearance and potential collision areas.

Simplification – Reduce polygon counts while preserving critical detail, ensuring models remain accurate but optimized for performance in real-time visualization and analysis.

Clash Detection – Quickly identify where parts intersect or interfere, allowing you to resolve design conflicts early in your workflow.

By combining these capabilities, Polygonica streamlines complex geometry handling, reduces manual repair work, and delivers models you can trust, saving both time and cost across your product development process.