Valiant TMS Merged Reality Concept

Valiant TMS & Tech Soft 3D

Valiant TMS is a global company powered by people working together to be the most trusted partner in delivering intelligent automation solutions. The company is a full-service Industry 4.0 system integrator leading the way in digitalization, process development, design and technology integration. Valiant TMS specializes in welding and joining, automated assembly and test, industrial parts washers and final assembly systems. The company was founded in Windsor, Ontario in 1959 and today operates from 24 facilities in 13 countries with 1,700+ team members serving companies in the automotive, aerospace and heavy industry sectors.

“What started as an idea and concept within our North American operation is now being used by our teams globally; growth and adoption is still accelerating as more people are exposed to the benefits it brings.”

Suresh Rama, Director, Business Intelligence and Innovation at Valiant TMS

We interviewed Suresh Rama, Director, Business Intelligence and Innovation, Raymond Slowik, Senior R&D Engineer, and Jaee Jadhav, Mechanical R&D Engineer from Valiant TMS about their experience of working with Tech Soft 3D and to discuss some of their current and future use cases.

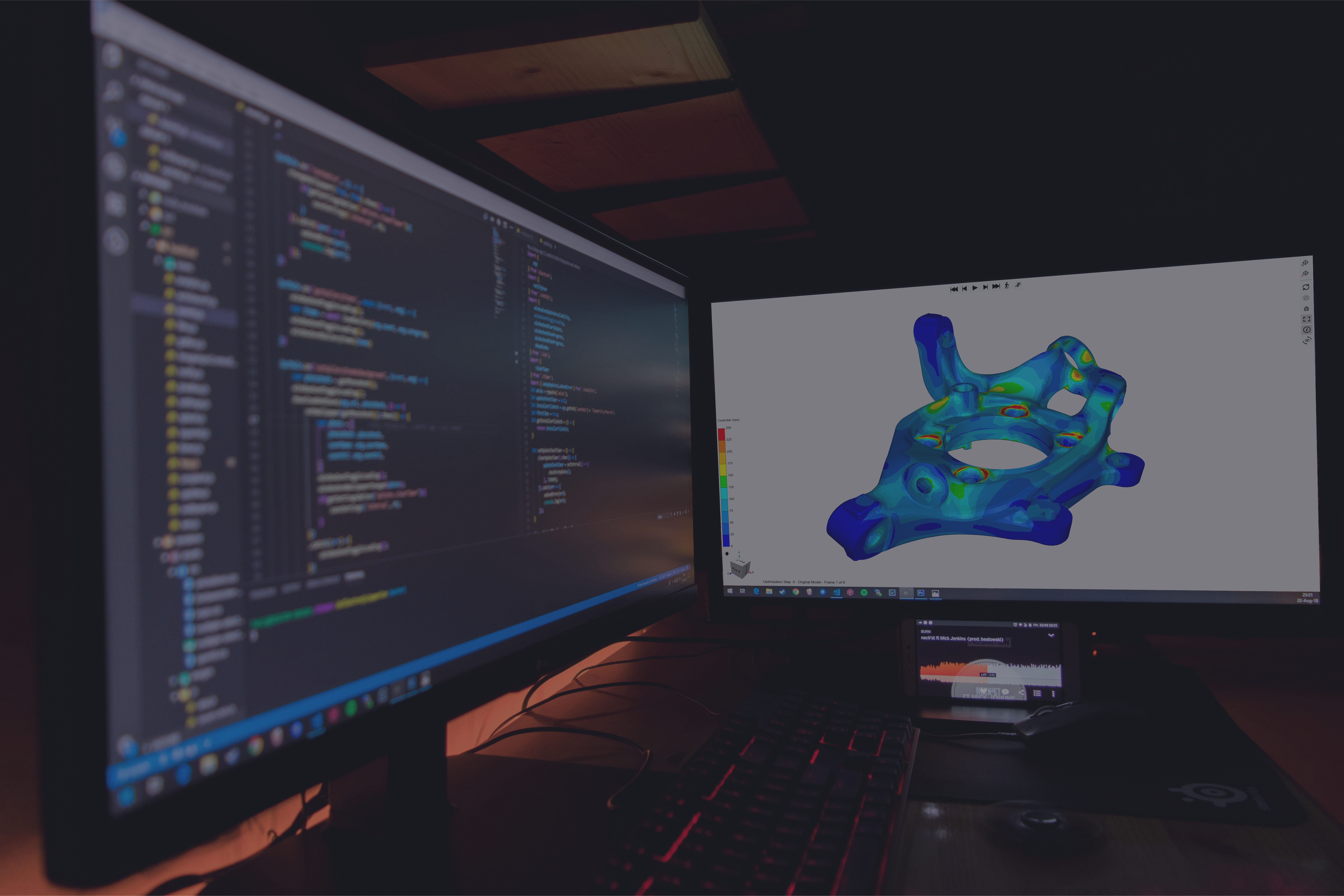

Valiant TMS started using Tech Soft 3D’s CAD conversion solutions about 10 years ago. When they began looking for a partner to help them develop a merged reality and IIOT concept, the direction Tech Soft 3D had taken with its’ XR visualization tools (with the use of 3D CAD content to create holographic models using the Microsoft HoloLens) had yet again made Tech Soft 3D the perfect partner.

How Did the Merged Reality Concept Come About?

Suresh: "I have a teenage son at home who is really into virtual reality and video games and one day it struck me that his experience growing up must be so different from mine when I was his age.

I assembled a team to begin studying virtual technologies and how we can apply them to our process of designing and integrating industrial automation solutions. We knew we were on the brink of a major shift in how the industrial sector uses technology as we were already seeing it infiltrate this space in small ways.

While my team dove into their research, I briefed our senior management team and received overwhelming support to continue down this path. Their forward-thinking attitude was centered on our ability as a company to serve our customers and align with their aspirations and vision of the factories of the future. As a trusted automation partner, our customers expect us to be leaders in this area."

"After comprehensive research, we selected Microsoft HoloLens as our hardware platform, and SpinFire XR as our software solution because of how well it worked with our existing 3D CAD data and aligned with our ideas and concepts.

Today, we have made significant progress. Many of our teams have adopted this technology and use it every day – they rely on it to perform at a higher level.

What started as an idea and concept within our North American operation is now being used by our teams globally; growth and adoption is still accelerating as more people are exposed to the benefits it brings. The COVID-19 pandemic has been a factor in increasing the rate of adoption because people need new ways to collaborate due to travel restrictions and health and safety concerns – the fact is that people still need to work in a team environment, they just need to do it from home instead of the office or plant."

How Did You Develop a Strategy for Applying New Technology?

Ray: "I was tasked with developing a strategy and concepts to leverage and apply new technologies, such as merged reality and IIoT (industrial internet of things), for Valiant TMS.

I spent a long time researching and examining various hardware and software technologies from several companies to determine how our vision and what we needed differed from or aligned with what was currently available. We realized that there are two potential paths to implement a merged reality solution.

One path is through the visualization and utilization of our 3D CAD content to create holographic models that can be used and manipulated in space and in the real world through head gear or other forms of visualization hardware. The other path was the utilization of information transfer, allowing individuals to quickly acquire knowledge based on directions provided through the visualization hardware. This is most often seen in instructional applications and many of the companies that we researched approached it from that direction.

Our focus is on design, build, and integration of automation equipment and specialized manufacturing technologies. We wanted to empower the people on our manufacturing team with effective tools that would allow them to engage with the CAD design data as they assemble the actual equipment with the ability to validate that it’s been done right."

"We also needed a better way to perform incoming material inspection, ensuring that it matches the approved design. Finally, we felt our customers could benefit from an immersive review of our design proposals to ensure that our equipment will comply with their requirements, specifications, and expectations.

Our vision aligned with what Tech Soft 3D was offering, so we decided to move forward with the solution"

What ROI Can Be Expected by Implementing Some of Your Use Cases?

Suresh: "We have several cases where traditionally it may have taken days to carry out a task, required travel time and related expenses and may have delayed our project timing. After adopting HoloLens with SpinFire XR and applying them to our process we’ve been able to do many of these tasks in a matter of hours, without having to travel. It’s much more efficient.

We have described several specific use cases to show some of the ways we have used the technology and realized benefits."

Use Case Example – Upgrade to Windshield Installation Robotic Cell

SpinFire XR software on the HoloLens was used to verify clearances and detect interferences at our customers' production plant. Valiant TMS used design models in the JT format which were virtually overlaid into the physical assembly line prior to building the toolkits.

Robotic assembly cell was approximately 1,500 ft² in size.

Inspection occurred on a regular workday during a 30-minute line stoppage at lunch.

Using HoloLens, the inspection was performed without the need to enter the cell and took approximately 1 hour in image collection and uploading for review.

Traditionally, a laser scan can take upwards of 5 hours to carry out and requires the line to be stopped and emptied with a lock-out tag-out (LOTO) procedure carried out for safety. That's why they are typically done off-shift or on a weekend.

Design engineers attended the on-site review and were able to visualize the tool changes from multiple angles in real time. This is not possible using the laser scan method.

Information was available to the engineers immediately after inspection. The laser scan method would not be available for at least 2 days (1 day scan, 1 day processing and delivery).

In Short

SpinFire XR has provided Valiant TMS with a unique opportunity to visualize 3D CAD models placed directly over real world equipment, tooling and components. Valiant TMS’ use of the software has improved their ability to quickly inspect tooling and components prior to acceptance from their vendors, ensuring that as-built components match as-designed plans, saving time and money at the assembly site.

Industry

Manufacturing

Challenge

They were looking to implement a merged reality concept, and were exploring how to implement new technologies like XR.

Solution

Multiple tasks that previously took days now take hours with SpinFire XR

Less travel is required, resulting in time and money saved and fewer delays to projects.

Results

At least 4 hours saved on processing scans/data

Data available immediately instead of waiting multiple days

Positive impact on project timeline