Fast, Reliable 3D CAD Data Access

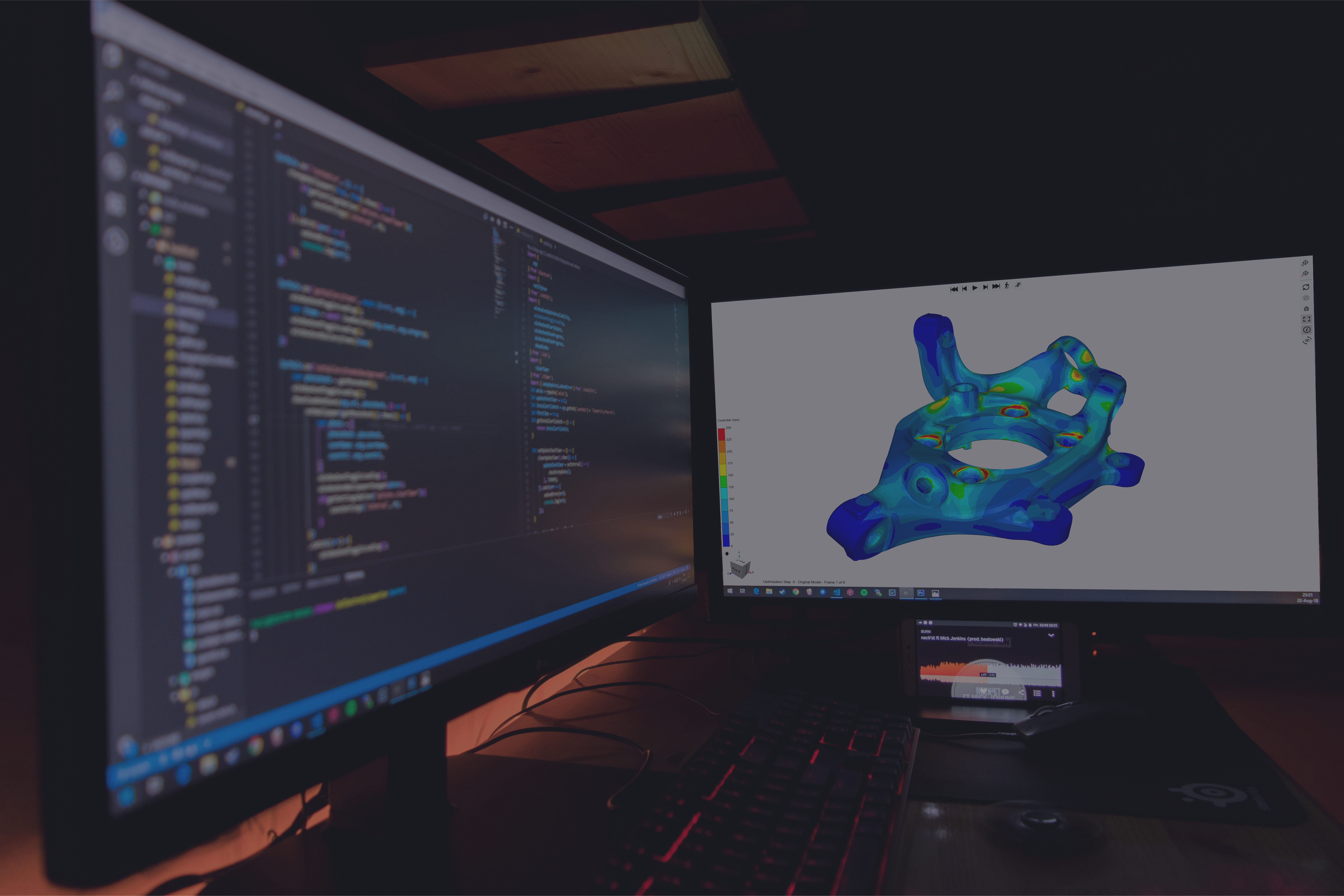

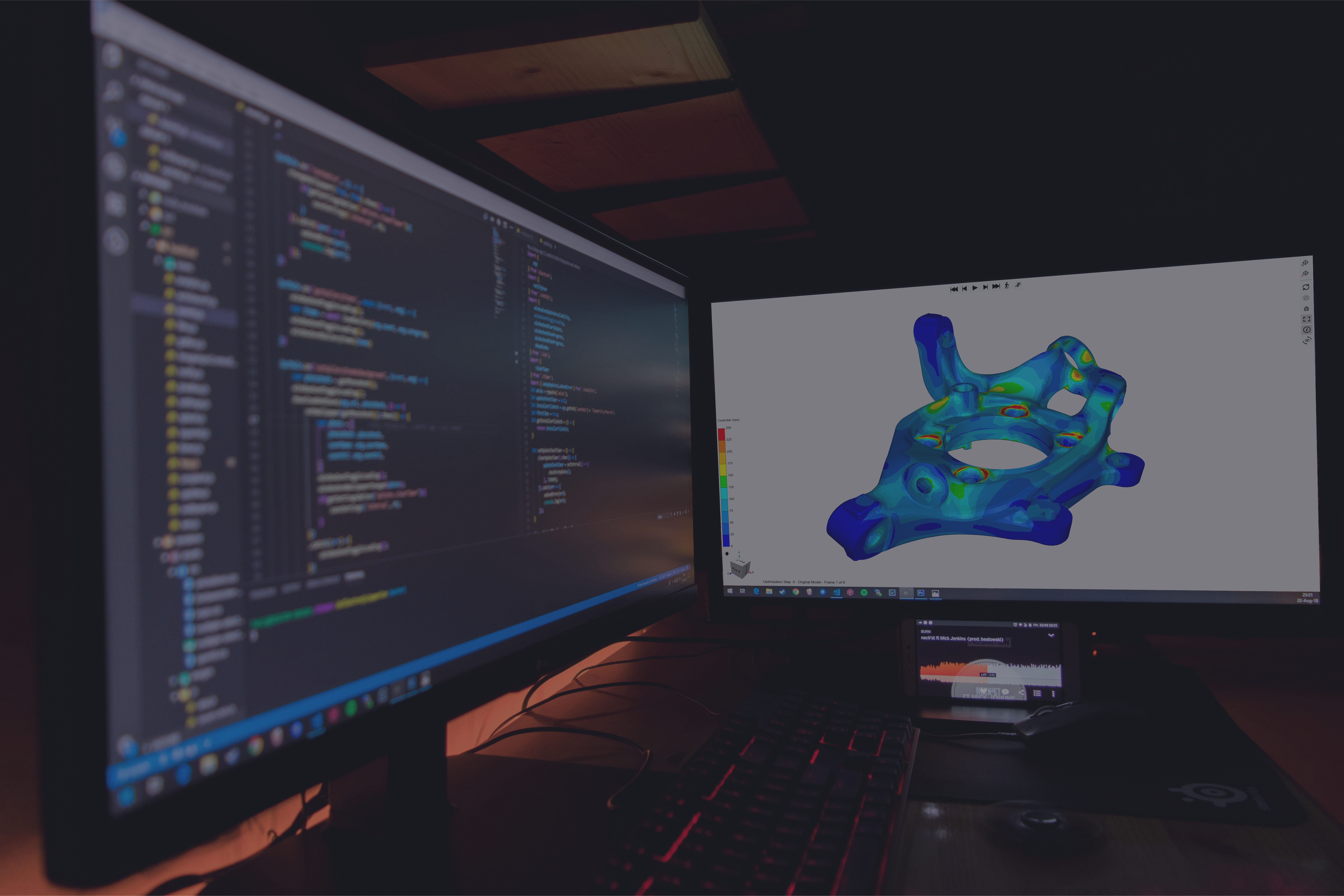

To support a broad cross-section of the industrial market, Halocline knew that it would need its flagship applications to work with as wide a range of data as possible.

“We have so many different companies that we work with, from small engineering departments at startups, to huge, well established automobile manufacturers,” said Schlarmann. “They’re all using different CAD systems and working with different file formats. How do we enable a seamless workflow for all of them?” HOOPS Exchange – the fastest and most accurate CAD data translation toolkit – represented an ideal solution for Halocline.

HOOPS Exchange includes all the integration tools a development team requires to easily build robust CAD data translation into an application, delivering a wide range of 3D data types in all major CAD and 3D formats. Crucially, HOOPS Exchange provides access to a broad range of data including boundary representation (BREP), product manufacturing information (PMI), model tree, views, persistent IDs, styles, construction geometry, visualization and more.

“It’s important to us to have access to that high level of detail, but to also be able to reduce the complexity of the model for optimal VR performance,” explained Schlarmann. “For planning the shop floor, we can abstract the information by turning complicated objects into boxes –that’s one of the ways we’re able to maintain great framerates of 90 frames per second. When it comes to assembly of an actual product, though, access to that detailed level of information is important to see how one part is connected to another during the assembly process – and HOOPS Exchange ensures that information is fully available when it’s needed.”

By relying on the HOOPS Exchange software development kit, Halocline is able to devote the majority of its time towards developing solutions that help manufacturers to efficiently integrate Virtual Reality into their operations.

“Our core business is designing great VR applications and great user interfaces that help optimize production processes involving people and machines,” said Schlarmann. “Importing CAD files is not our core business – and that’s why we rely on strong partners like Tech Soft 3D.”