Building Shipbuilding Software with Tech Soft 3D Toolkits

Developers creating applications to serve the shipbuilding industry face a sea of problems (bad pun, we know, couldn’t resist).

Shipbuilding projects regularly span years or decades, with models growing to enormous sizes while combining data from a wide range of sources. The applications that serve this market are often developed by smaller, specialized teams, with the expectation that they will remain reliable long after other tools have changed.

Tech Soft 3D has provided developers with engineering-focused Software Development Toolkits (SDKs) for 30+ years, serving complex markets from aerospace to automotive and, of course, shipbuilding. In shipbuilding, where long lifecycles and deep domain expertise are the norm, that experience matters.

Here, we discuss the unique challenges developers of shipbuilding applications face, why toolkits may be well-suited to cut costs and improve their final product, and which Tech Soft 3D toolkits fit your needs. From visualizing vast models and simulation components to accessing data without compromising information integrity, these tools offer features perfect for industry challenges.

The Unique Challenges of Developing Shipbuilding Software

Shipbuilding applications come in all shapes and sizes, developed by everyone from different-sized commercial vendors focused on marine-specific workflows to internal groups within shipyards and more. While they have sharp differences, shipbuilding developers share a common set of obstacles.

Titanic Model Scale

Perhaps the most obvious and largest problem that developers face is scale. Ship CAD models routinely include millions of data-rich components spanning hull geometry, structure, piping, electrical systems, and equipment. Engineers need to navigate these models interactively, isolate relevant regions, and review design intent without sacrificing performance. Successful applications need to balance visual fidelity and performance, with framerate and responsiveness as key considerations.

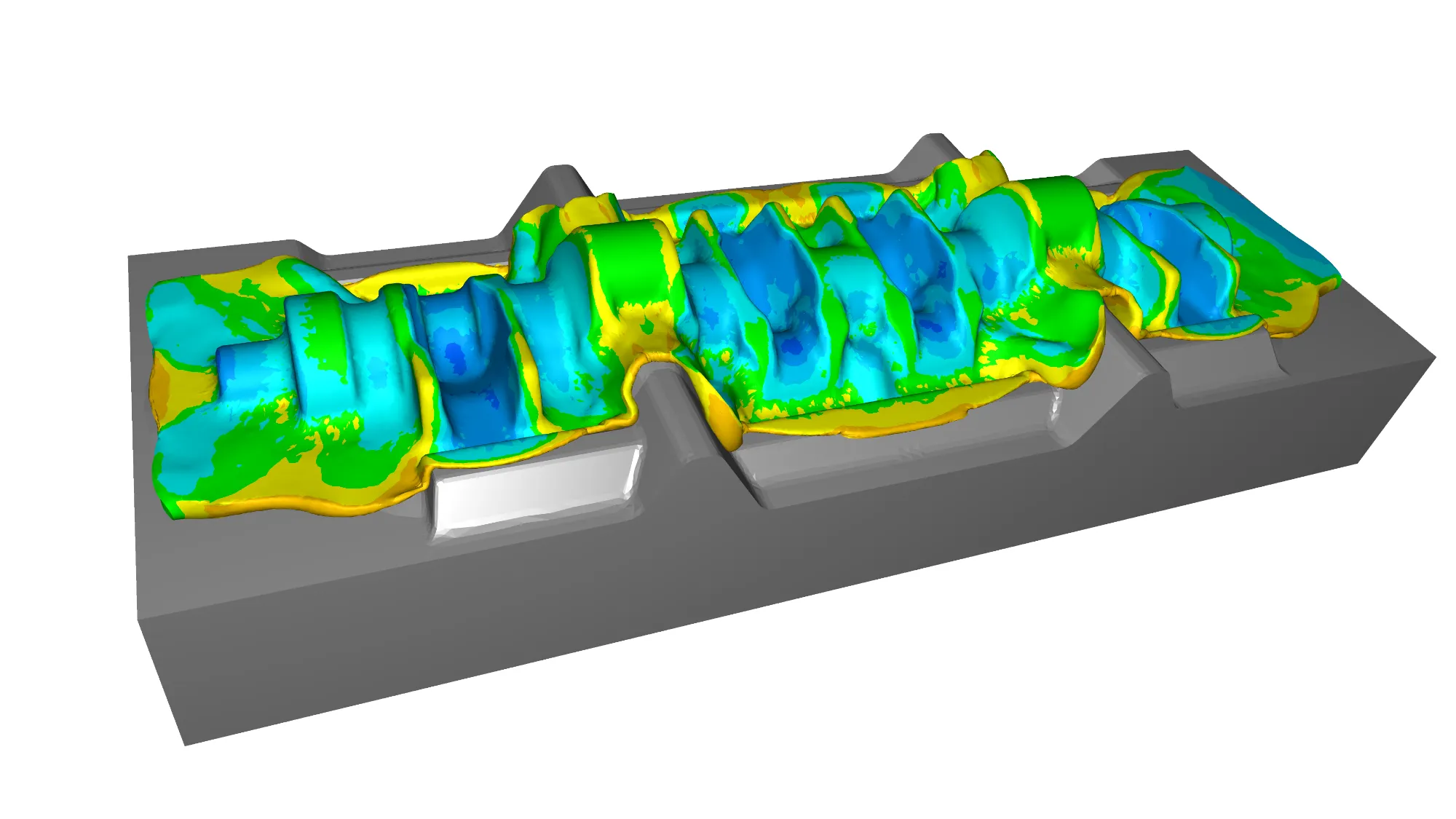

Scale challenges also extend beyond CAD. Reality capture and point cloud workflows are increasingly common in retrofit planning and asset management, where teams need to compare the conditions of something as it was designed to how it is currently. This demand to support point clouds alongside CAD geometry adds another layer of performance and navigation difficulties for developers creating shipbuilding applications, especially when measurement and sectioning are required.

Data Diversity and Integrity

Another defining challenge is data fragmentation. Shipbuilding workflows rely on an eclectic mix of general-purpose CAD systems, marine-specific design tools, and in-house applications. Models are frequently assembled from multiple sources rather than authored in a single system. This federated approach requires software developers to create applications that can handle a wide variety of formats, levels of detail, and associated metadata. Access to geometry alone is rarely sufficient, with product structure, attributes, and engineering context being just as important.

Additionally, future data interoperability has to be maintained. Frequently, new analysis requirements appear mid-project. Additionally, design and maintenance cycles in shipbuilding are long, with tools and file formats changing as they do. Throughout the process, legacy data cannot be discarded or corrupted. For the typically smaller development teams of shipbuilding applications, these create time-consuming, expensive recurring maintenance.

Developers of modern shipbuilding applications should be aware that 3D models are increasingly central to shipbuilding workflows. Decision-makers now expect to provide feedback and work directly with 3D models, with all the relevant supporting data easily accessible. Emerging initiatives such as OCX (Open Class 3D eXchange) are supporting this shift, though adoption is anything but uniform.

Simulation and Analysis

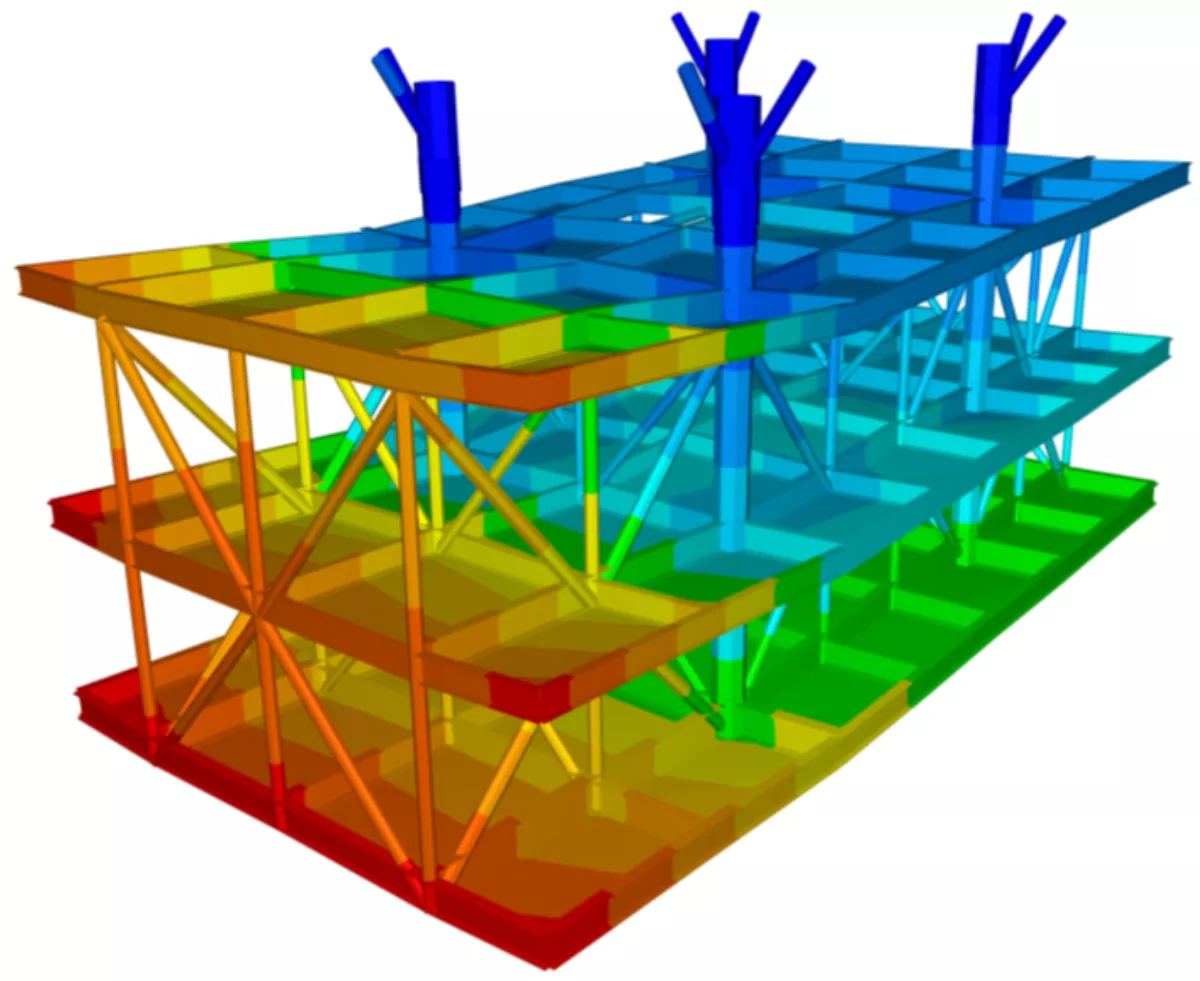

Demands surrounding simulation and analysis add another layer of complexity for developers to address. Structural analysis, hydrodynamics, vibration, thermal, and acoustic studies all play a role in ship design. The results of these multimodal analyses inform ongoing design decisions and must be reviewed in context with the underlying geometry. Visualization of CAE results becomes part of the core engineering workflow rather than a separate post-processing step. Applications often need to work with common simulation applications while also providing key CAE features themselves

Increasingly, these workflows are distributed or run in the cloud, requiring developers to support remote engineering features, including browser-based CAE results.

How Tech Soft 3D Toolkits Support Shipbuilding Software Development

The challenges described above create a series of needs for shipbuilding software that toolkits are well placed to serve. These include:

High-performance visualization that can handle extreme model sizes.

Broad and reliable access to CAD and CAE data from many sources.

Geometry and mesh tools that can support downstream workflows without forcing them to reimplement low-level functionality.

Components that remain viable across long deployment timelines.

These needs become even more pronounced as shipbuilding organizations invest in digital twins, model-based collaboration, and long-term lifecycle workflows that depend on consistent engineering context.

Visualization at Extreme Scale

High-performance visualization is a core requirement in shipbuilding. Ship models often contain millions of components, and engineers must be able to navigate them interactively, isolate regions of interest, and review design intent without performance degradation.

HOOPS Visualize is designed to support the strenuous performance demands that come with interacting with assemblies that feature tens of thousands (or more) components. This high-performance graphics engine offers its industry-leading graphics for web, desktop, and mobile applications, with support for C++, C#, JavaScript, and TypeScript.

The toolkit offers core functionality that modern shipbuilding applications are expected to have, including markup, selection, sectioning, point clouds, and detailed model navigation tools. Utilizing an SDK allows developers to focus on domain-specific behavior rather than building and maintaining a complex rendering engine.

HOOPS Visualize provides features key to model-based review workflows anywhere, including those that require remote collaboration. You can explore the demo viewers to see for yourself below.

Data Access – Supporting Interoperability Across General and Marine-Specific Systems

With the diversity of tools leveraged in the CAD ecosystem of shipbuilding, developers need to support workflows featuring models assembled from many data sources. HOOPS Exchange and HOOPS Access provide consistent access to geometry, assembly structure, PMI, and metadata across a broad range of CAD and CAE formats.

HOOPS Exchange is the industry-leading CAD data access toolkit, offering support for 30+ formats, including those most important to shipbuilding applications. With unmatched speed and data integrity preservation, HOOPS Exchange directly supports combining federated data into a single model, without flattening data into a monolithic representation. For developers, this reduces the complexity and maintenance burden of supporting diverse and evolving data sources.

HOOPS Access provides applications with access to CAE formats, allowing your tool to expand its interoperability with the simulation tools popular in shipbuilding workflows.

Geometry, Model Preparation, and Hull Workflows

Beyond visualization and data access, many shipbuilding applications require direct interaction with the geometry of models themselves. Hull modeling and editing, simplification for visualization, and mesh repair for simulation are common requirements, particularly when working with large or complex models.

Geometry modelling toolkits such as Parasolid and Polygonica allow developers to work with precise geometry and to prepare models for downstream use without building these capabilities from scratch.

Tech Soft 3D is a proud reseller of both Siemens’ Parasolid, the leading solid modeling kernel, and MachineWorks’ Polygonica, a powerful option for 3D meshing processing. Our close collaboration with Siemens and MachineWorks allows us to offer seamless integration with HOOPS toolkits, ensuring developers spend less time integrating these tools.

HOOPS Mesh offers reliable 2D and 3D meshing for the model your shipbuilding software will handle daily, while HOOPS Solve supports the creation and optimization of FEA algorithms for simulation and analysis.

CAE Results in Engineering Context

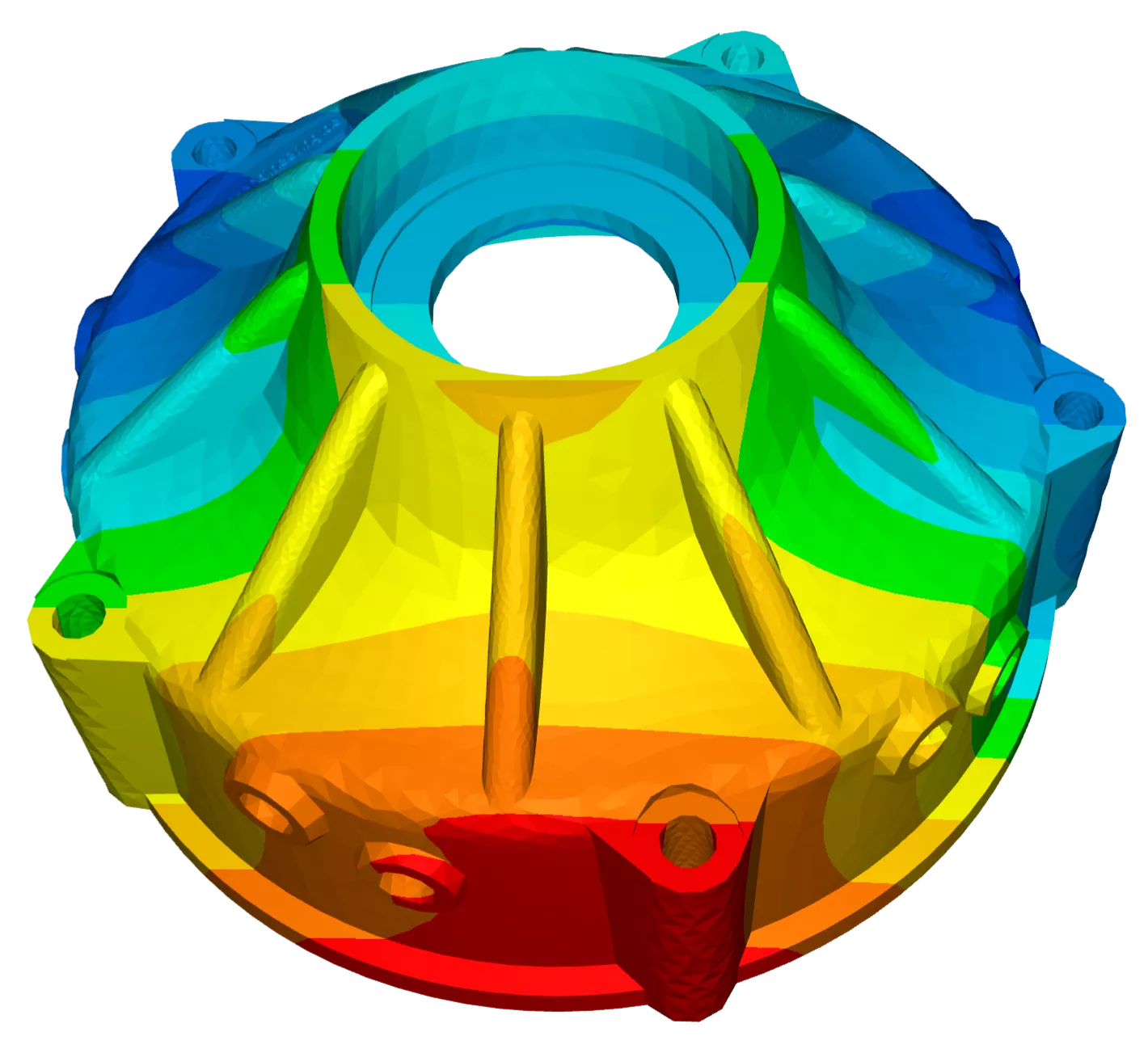

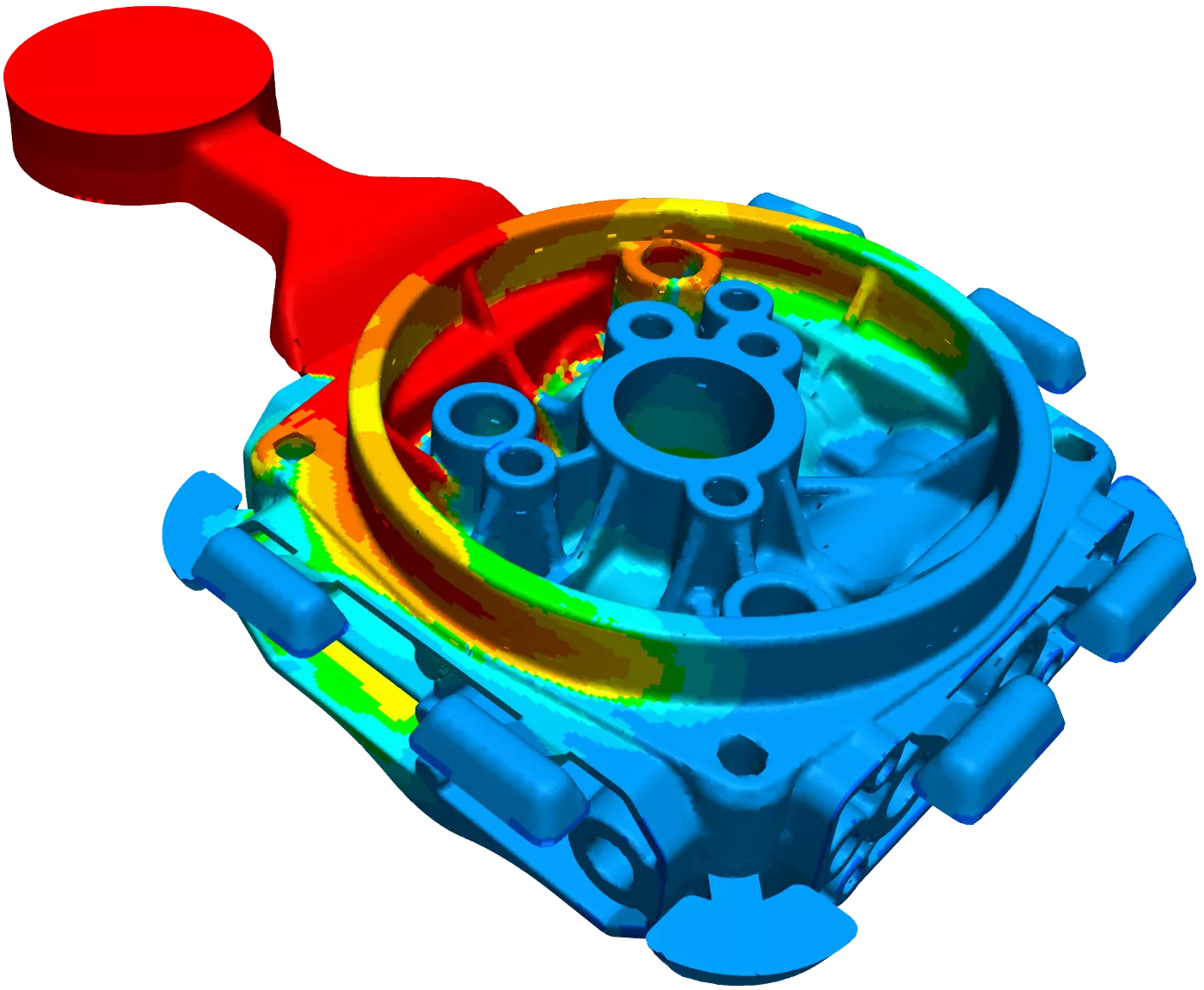

HOOPS Envision serves the entire CAE workflow, from import and analysis to visualization, reporting, and automation. The toolkit imports results from common FEA tools, quickly visualizes the data, and provides tools for deep results interogation.

This toolkit can offer its capable functionality for both desktop (OpenGL) and browser-based web (WebGL) applications. The web version offers server-side rendering, delivering powerful, desktop-like performance to remote clients.

By enabling results to be viewed in context with the design, these toolkits help developers integrate analysis more directly into engineering workflows rather than treating it as a separate post-processing step.

Supporting the Shipbuilding Applications Engineering Workflows of The Future

Many shipbuilding organizations are exploring approaches such as digital twins, cloud-scale simulation, and remote engineering. While the exact execution of these trends varies, they typically increase the demands they have for applications’ visualization performance, data access, and long-term maintainability.

Tech Soft 3D toolkits support these needs by providing the underlying capabilities that such architectures depend on, without prescribing a single implementation model. Our toolkits offer the core server-side rendering, web-based visualization, and support for more stable data pipelines features that the next generation of shipbuilding tools require.

In an industry built on long timelines and experience, history matters. We encourage you to explore our partner success stories to learn more about our track record of success in supporting application development, including those specific to the shipbuilding industry.

Whether a shipbuilding tool is intended for commercial distribution or deployed internally within a shipyard, the underlying technical challenges remain largely the same. Performance at scale, interoperability across diverse systems, and the ability to sustain software over long lifecycles are persistent concerns. Tech Soft 3D focuses on providing components that help development teams meet those challenges and build software that matches the realities of shipbuilding engineering.