Additive Manufacturing

Modern additive manufacturing and 3D printing software require a combination of robust data access, 3D visualization, and mesh processing capabilities. Tech Soft 3D’s SDKs enable you to add these capabilities to your software, streamlining your development process.

Trusted by Stratasys, 3D Systems, Desktop Metal, and Xometry, Tech Soft 3D’s HOOPS SDKs and MachineWorks' Polygonica provide the core technologies powering additive manufacturing software.

With the ability to access CAD data, visualize in 3D, automatically heal and simplify meshes, you have everything you need to accelerate development and deliver robust, production-ready applications.

Additive manufacturing often begins with complex CAD models, and those models come from a wide range of sources. Supporting multiple file formats in-house is a costly and time-consuming challenge, especially when accuracy and speed are critical.

HOOPS Exchange solves this by enabling your application to import over 30 native and standard CAD file formats out of the box, including SOLIDWORKS, CATIA, Creo, Inventor, STEP, and STL. Beyond geometry, it provides access to rich manufacturing data, including PMI, metadata, and assembly structure.

With its high-performance libraries and easy integration, HOOPS Exchange lets you focus on innovation, not file translation.

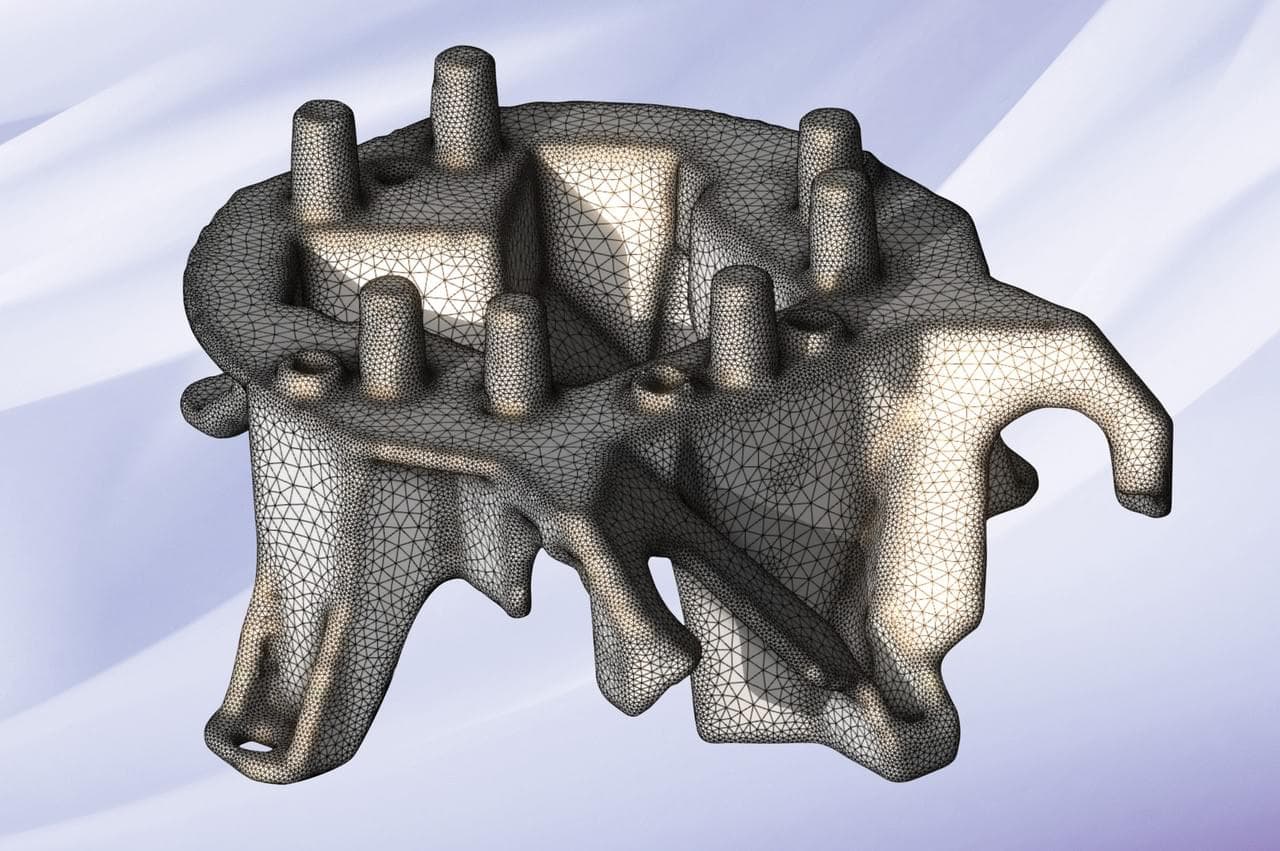

Preparing models for 3D printing often involves fixing messy, non-watertight meshes that can derail print jobs. Polygonica simplifies this process with advanced tools for mesh repair, cleanup, and optimization. It enables users to fix geometry issues, reduce complexity, slice models for printing, hollow parts to save material, and generate lattice structures for strength and efficiency. Polygonica helps ensure your models are print-ready, reliable, and optimized for additive manufacturing.

Clear 3D visualization is essential for validating models before printing or manufacturing, but building a custom engine takes time. HOOPS Visualize gives you high-performance 3D graphics and interactivity across web, desktop, and mobile platforms, so you can focus on what makes your software unique.

Case Studies

No content found.

There are currently no items that match this selection. Please adjust your filters or check back soon for updates.

Frequently Asked Questions

What is additive manufacturing and how does Tech Soft 3D support it?

Additive manufacturing (AM) is a production process where objects are built layer by layer from digital models. Unlike traditional subtractive methods that cut away material, AM adds material precisely where needed, enabling complex geometries and efficient material use.

Tech Soft 3D supports additive manufacturing through powerful software development kits (SDKs) that are embedded in many leading AM applications. These include:

HOOPS Exchange for fast, reliable CAD data translation and access

HOOPS Visualize for high-performance 3D rendering and interaction

Polygonica for advanced mesh processing, including repair, simplification, slicing, hollowing, and lattice generation

How does Polygonica help with 3D printing workflows?

Polygonica improves 3D printing workflows by preparing mesh models to be clean, watertight, and print-ready. It automatically detects and repairs common issues such as holes, self-intersections, and non-manifold edges. With Polygonica, you can clean up and optimize meshes, simplify geometry, slice models for printing, hollow parts to save material, and generate lattice structures to reduce weight and maintain strength.

Can I add Tech Soft 3D's SDKs to my existing additive application?

Yes, Tech Soft 3D's SDKs can be added to any new or existing application. If your application already uses other SDKs or custom-built tools, switching to Tech Soft 3D’s technology is possible. Depending on your architecture, some additional configuration may be required to ensure compatibility. Tech Soft 3D's team is here to help you integrate SDKs into your application, regardless of where you are in the process.

Can I evaluate Tech Soft 3D's SDKs for my additive manufacturing or 3D printing application?

Yes, you can evaluate our SDKs for free to determine if they're the right fit for you. Our HOOPS SDKs have a 60 free evaluation trial period, which you can start at manage.techsoft3d.com.

Polygonica also has a 60-day evaluation period. To start your evaluation, please contact us.