Visualization Experience

Review 3D CAD and PLM design data using XR technology, at full scale and in context.

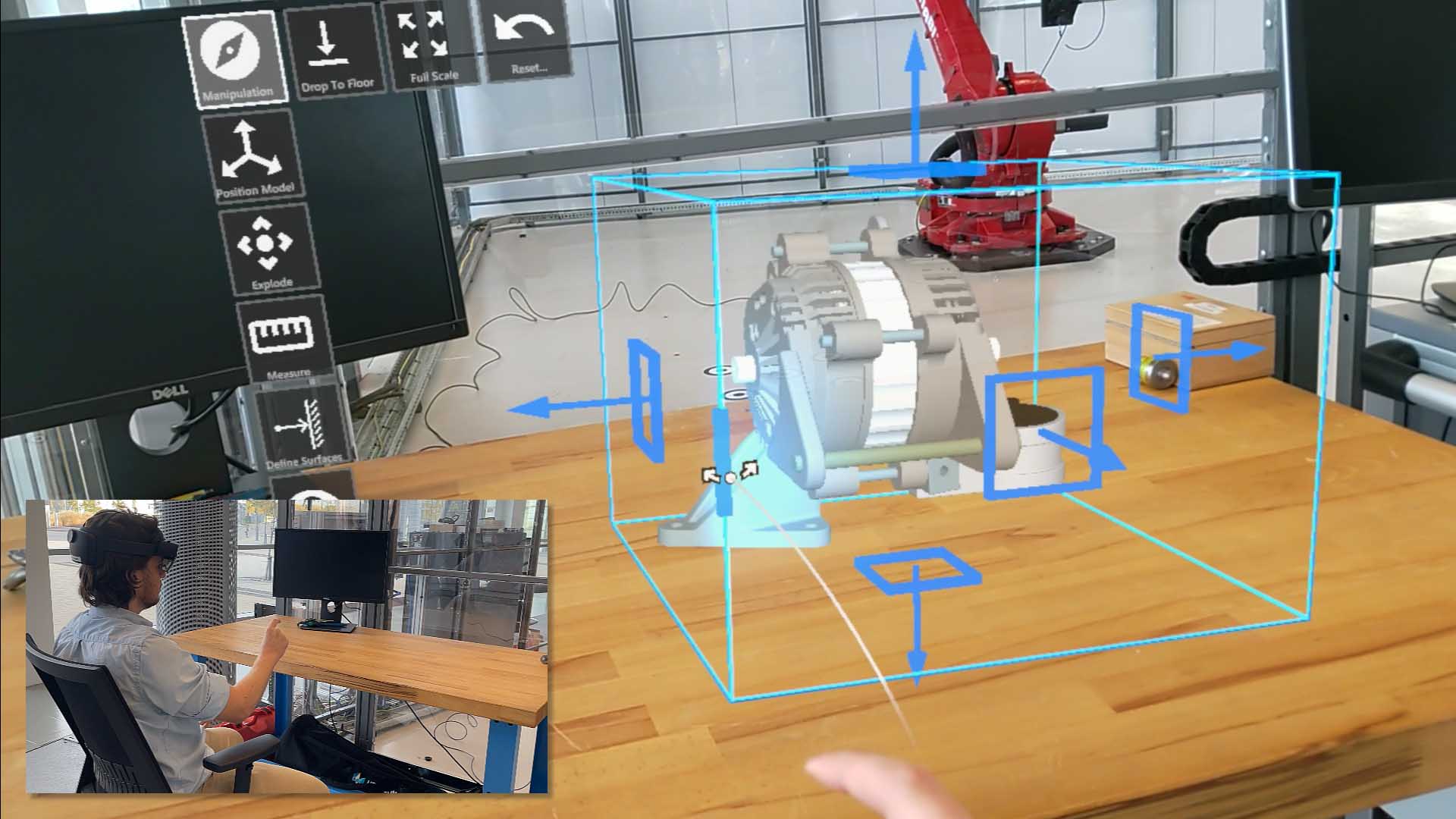

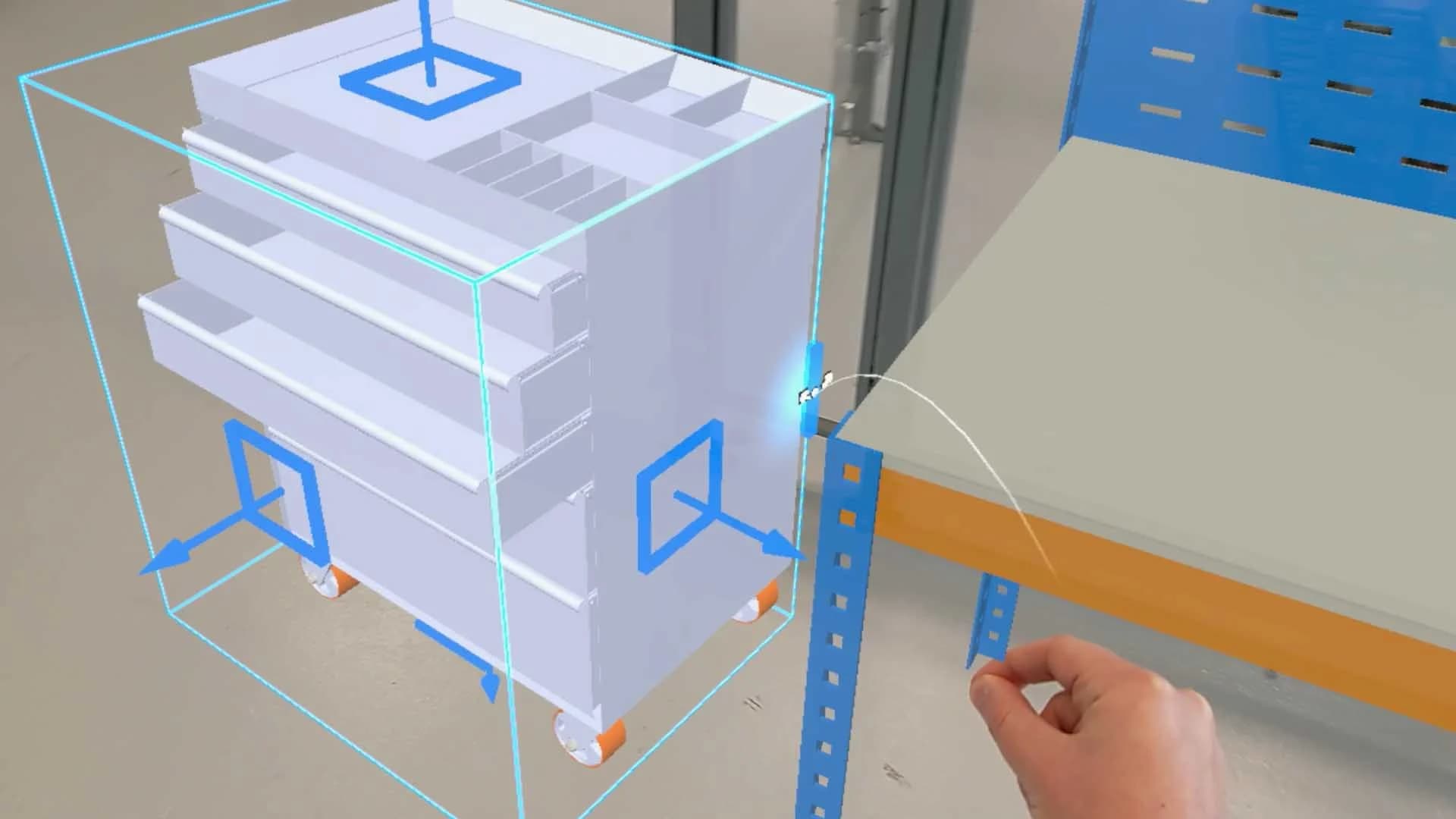

The Visualization Experience provides the ability to review 3D assets, and view 3D models at full-scale, in whichever XR output device a user chooses. The application is available in Virtual and Mixed Reality headsets, and on desktop and laptop devices. Exploiting the power of ‘consumer XR’, the application empowers engineers to inspect 3D data in a spatial context, visualizing their models at full scale.

Engineering companies’ most valuable 3D asset is their CAD data, but traditional CAD restricts users to viewing models on a 2D screen, without true scale or real-world context.

The Visualization Experience overcomes this limitation by immersing engineers in their designs at full size and in context. This allows scale and spatial relationships to be understood instantly, accelerating design decisions and early identification of costly errors.

Products can be experienced within a complete digital environment before physical available, or in real-world settings such as offices, showrooms, or factories. By enabling engineers to see their products as they truly exist, the Visualization Experience closes the cognitive gap between CAD data and real-world understanding.

Automated Data Processing

Preparing data for the Visualization Experience is a seamless fully automated process using the Visualization Pipeline. You can “save as” from your CAD session, drag and drop from the file system or drive it directly from your PLM workflow.

FAQs about the SpinFire XR Visualization Experience

Does the Visualization Experience support full-scale visualization?

Yes. The Visualization Experience supports full 1:1 scale visualization for Virtual and Mixed Reality users. It provides tools to view, navigate, explode, section, and measure data at true scale, alongside key product information such as CAD metadata.

Virtual Reality: Users can experience 3D models at full scale within a virtual scene, including environments that are inaccessible or not yet built.

Mixed Reality: Users can place holograms of 3D assets into the real world at 1:1 scale. This gives accurate spatial context for design reviews and helps prevent costly issues, such as clashes with physical models, before manufacturing begins.