Factory Layout Experience

Enable collaborative digital planning and layout at scale in XR

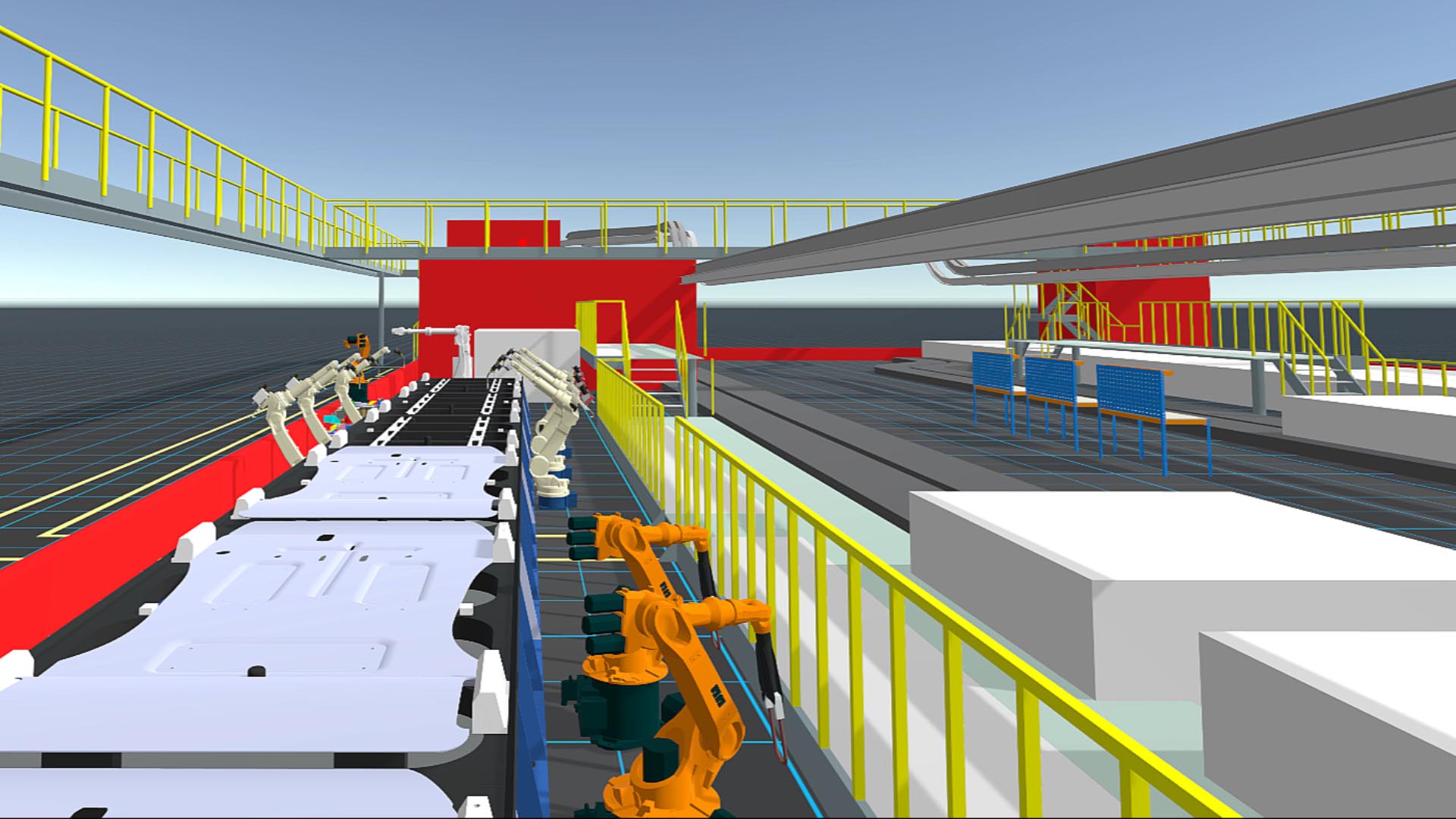

The Factory Layout Experience helps engineers and planners to design and validate production environments at full scale using XR.

Users can seamlessly access a comprehensive library of CAD assets such as tooling, fixtures, machines, workbenches and production lines to build and refine layouts directly within the immersive space.

Whether working independently or collaborating with remote teams, the Factory Layout Experience helps identify space constraints, access issues and potential clashes that traditional 2D screens often miss. By validating factory layouts in context, teams can optimize workflows, improve task time efficiency and reduce costly rework before physical implementation.

The Factory Layout Experience allows you to design and plan your factory layout before anything is built, placing equipment, workstations and production lines virtually to validate flow, spatial constraints and operational fit. You can also step into your actual facility using Mixed Reality, overlaying CAD or using point cloud data to visualise how designs integrate with the real environment.

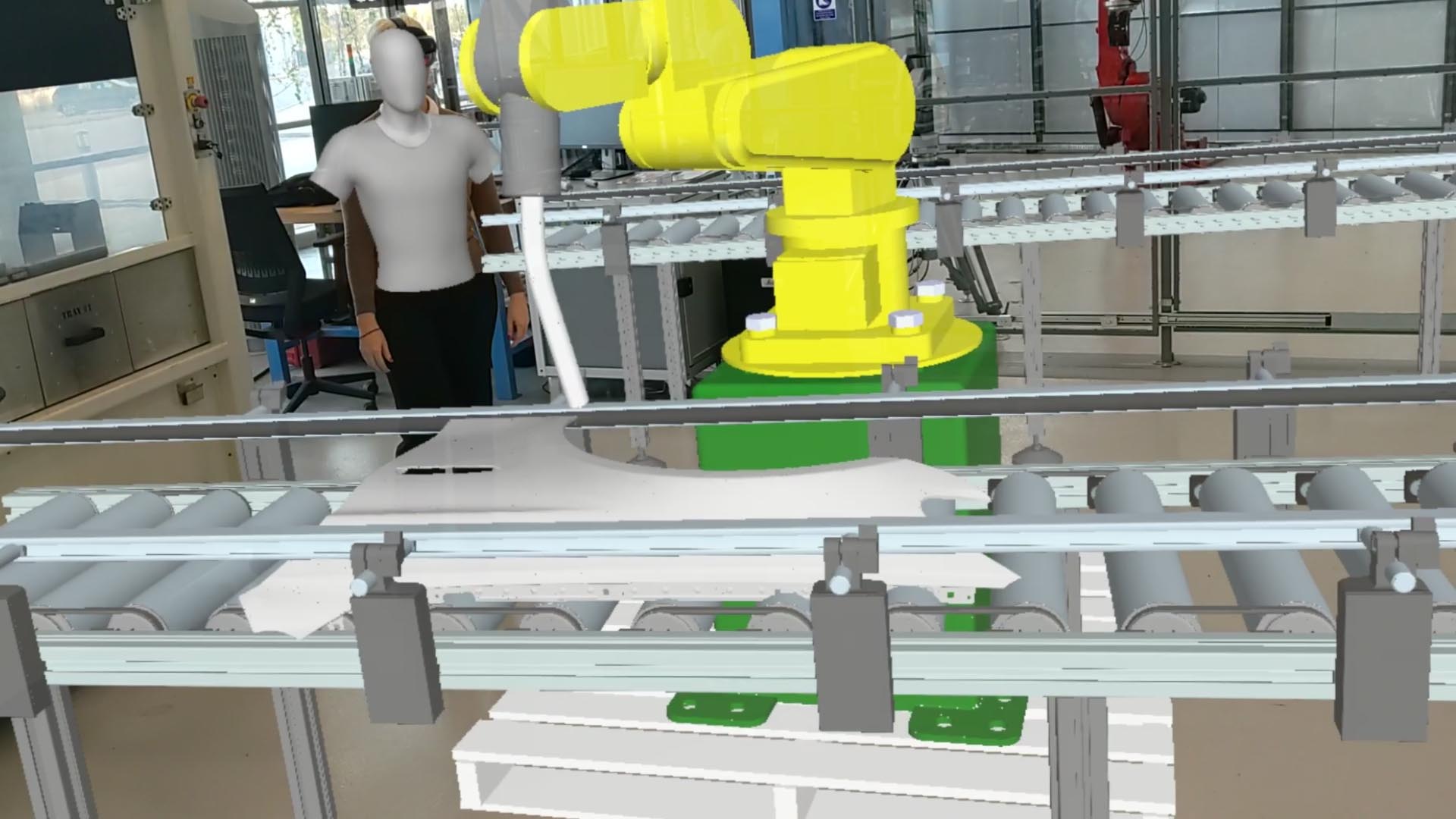

Let engineers and stakeholders become the mannequin, assessing tasks from the point of view of a real operator. This first person, immersive evaluation helps identify ergonomic issues, access constraints and safety risks early in the process. By simulating real world interactions virtually, teams reduce late stage changes, ensure compliance and avoid costly rework.

Effective layout planning requires input from engineering, manufacturing, operations and safety teams. SpinFire XR enables these stakeholders to meet in real time, on site or remotely, to review and validate layouts at full scale in the same immersive XR session.

Teams can assess equipment placement, process flows, operator tasks and safety zones in context, making informed adjustments before anything is physically implemented. Feedback is captured in session through comments, screenshots, voice notes or video, creating a clear record of decisions.

This collaborative workflow reduces misalignment, shortens planning cycles and helps avoid costly late stage layout changes.

Automated XR Data Processing

Preparing data for the Factory Layout Experience is a seamless fully automated process using the Visualization Pipeline. You can “save as” from your CAD session, drag and drop from the file system or drive it directly from your PLM workflow.

FAQs about Factory Layout Planning

Do all users need the same XR devices to collaborate in Factory Layouts?

No. Users can join collaborative Factory Layout sessions using different XR devices, including Mixed or Virtual Reality headsets. Users without XR headsets can join via desktop or laptop devices to view and interact with the layout in real time.

Why use Virtual Reality for factory layout planning?

Virtual Reality (VR) brings all your factory layout data together in a fully digital environment.

Unlike a 2D screen, VR lets you view everything (new robot cells, workstations, and more) in the context of the entire factory at full scale, providing immersive and spatial perspective.

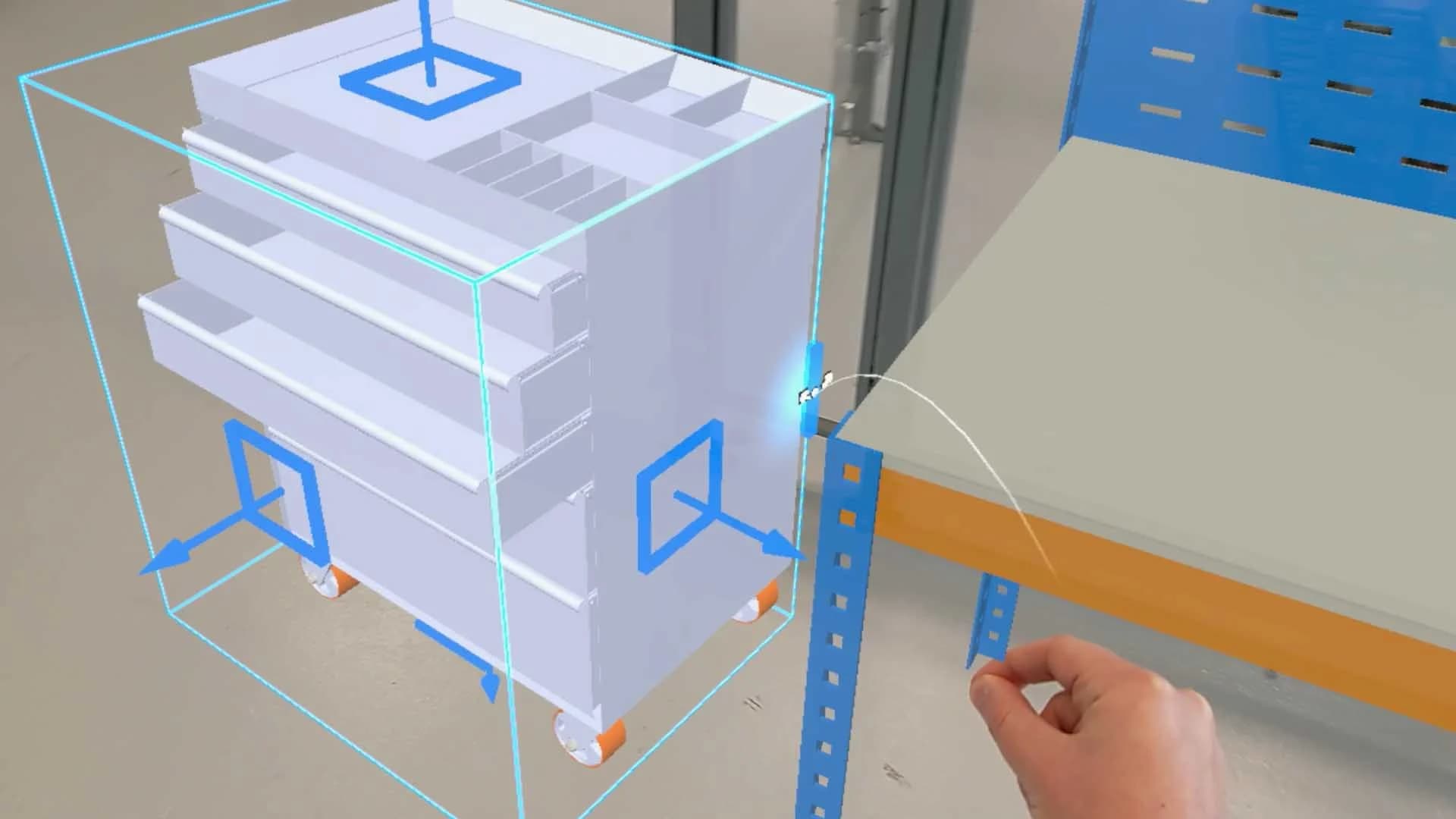

Why use Mixed Reality for factory layout planning?

Mixed Reality (MR) places your digital data into your real-world factory environment with 3D holograms.

For example, you can position a 3D hologram of a new robot cell in its intended spot on the shop floor, to see how fits and ensure there are no clashes, avoiding costly errors.

Everything around you is real - only the new data is digital. Using Mixed Reality helps to reduce ambiguity through contextual placement of virtual elements in the physical world.

Can I use XR to perform Time and Motion studies during factory layout planning?

Yes. Using features like Path Analysis, XR is a powerful tool for conducting Time and Motion studies in manufacturing environments - especially during the factory layout phase.

You can capture real operator workflows in XR to validate and improve your factory layout. Using a headset, SpinFire XR records movement, head and hand positions, plus object interaction to reflect how tasks are performed in real working conditions, that can be used to support task time analysis and continuous improvement.

By simulating task execution virtually, engineering teams can identify bottlenecks, reduce wasted motion and improve ergonomics before anything is built.

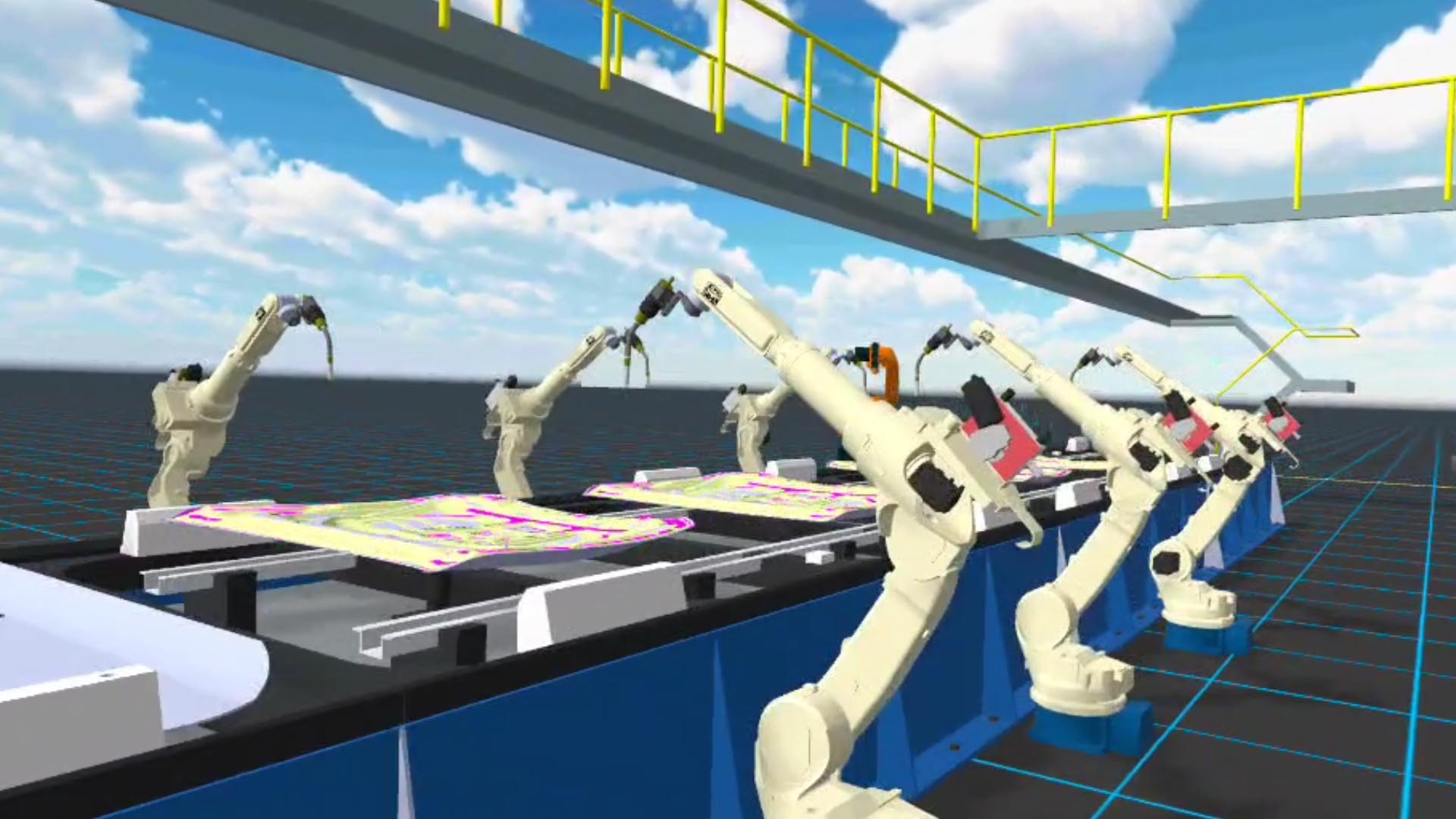

Can I visualize machine and robot animations in XR for layout validation?

Yes. With Animation Play Back in XR, you can visualize the animations of machinery, robots and automated systems - in context and at full scale - using animations from your CAD platform.

By simulating real world operations in XR, teams can validate machine paths, detect potential collisions and assess safety zones, particularly in collaborative robot environments. Combine movement data with human centric layout planning to evaluate access, reach and ergonomics, reducing the risk of costly layout changes and improving operator safety before anything is built.

Can I use CAD models to build factory layouts?

You can quickly build factory layouts by accessing your complete library of CAD assets, such as workstations, robot cells, tooling and production lines, directly within an XR environment.

Using SpinFire XR, all models uploaded to the Visualization Pipeline server are readily available in the app, eliminating the need for manual data preparation or switching tools. This streamlined access speeds up layout planning, allows teams to iterate faster, and ensures consistency across departments by using approved CAD models.

How can I gather and incorporate feedback during the factory planning process?

Effective communication is critical to avoiding costly misalignment during layout reviews. XR technology helps ensure design feedback is clearly communicated, reducing costly errors.

With SpinFire XR, you can capture feedback in real-time, right inside the app, eliminating the need to write up notes after the session. Add voice notes, comments, images or video clips directly linked to specific layout elements, so your feedback is clear, contextual and actionable.

All captured inputs are stored securely on the SpinFire server, making it easy to revisit discussions, share insights with stakeholders who couldn't attend or continue the review process.

How do I walk someone through a virtual factory in XR?

XR makes it easy to explore and guide others through large-scale layouts like factories and plants. This can also be useful for virtual tours.

With SpinFire XR, users can freely move around environments in single-user or collaborative sessions. Other useful features include:

Mini Map: Provide a scaled plan view to help users stay oriented and navigate through factories and other large layouts.

Waypoints: Create, edit, and save waypoints to instantly teleport between different areas - ideal for guided reviews, training, and remote walkthroughs.

Related Insights on Extended Reality (XR)

No content found.

There are currently no items that match this selection. Please adjust your filters or check back soon for updates.